The overcurrent fault protection (OFP) in heat treatment

Safe control of the heat treatment system process with electronic fuses

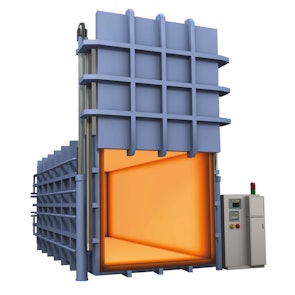

Temperature adjustment and control are critical in heat treatment applications

The overcurrent fault protection (OFP) fuses are usually used to protect systems from breakdowns. But these fuses are very expensive because they involve very precise and repeatable melting energy.

Gefran has patented a new solution that guarantees savings in terms of cost of replacement parts, labor, and down-time.

Temperature adjustment and control are critical in heat treatment applications. Industrial heating is usually done by means of heating elements with load – resistances, infrared lamps, silicon carbide or MoSi2 elements – controlled by a power controller.

The standard electrical panel also has temperature probes (TC, RTD) to acquire the process temperatures to be controlled and one or more PLCs to manage and supervise the system.

Protecting systems from breakdowns

Extra-rapid fuses are usually used to protect systems from breakdowns. But these fuses are very expensive because they involve very precise and repeatable melting energy. In addition to the cost, you have to consider that very often the wrong replacement fuses are used due to failure to check all of the nominal data and in case of urgent maintenance.

The wrong replacement fuse will restore system function in the short-term, but exposes the controller to risk of breakdown (melting of internal SCR devices) the next time the load short-circuits.

Gefran’s patent

To eliminate these problems, Gefran has patented the function of the Overcurrent fault protection (OFP) integrated in the Power Controller (European Patent No. 2660843).

The HW protection in the Power Controller can:

- detect a short circuit or external overload

- switch off the load

- safely discharge all of the opening energy of the fault loop

Therefore, in case of a load short circuit or overload, the Power Controller eliminates the short circuit, reducing the I2t opening energy to levels low enough to ensure that the external device that protects the power line does not trip.

By using multiple Power Controllers with electronic fuse, you can create short circuit protection solutions for 2-phase or 3-phase applications.

The Power Controller with electronic fuse can also be programmed to quickly and automatically reset the conduction load (with Soft-start ramp in Phase-Angle modulation) if the fault is easily resettable, thereby avoiding down-times while waiting for the operator to take action.

Protection system response speed

What is the protection system’s response speed? When the short circuit occurs, the controller detects the presence of a load short circuit (or overload) within 100 ms, shuts off the power module and, within another 150 ms, safely switches off the fault loop.

All of these steps are usually performed by line protection fuses or circuit breakers, using quartz sand (in fuses) or a special arc-quenching chamber (in circuit breakers), whereas the Power Controller with the overcurrent fault protection (OFP) eliminates the short circuit directly in the solid-state device (silicon) and thus without any arcs.

Gefran’s device eliminates the need for extra-rapid fuses and provides real savings in terms of cost of replacement parts (fuses), labor (repair of system breakdown), and down-time (lost production / alteration of process).

The device can also be programmed to automatically reset the conduction load if the short circuit or overload ends spontaneously, thereby eliminating the time and cost of manual action by the operator.

NB: the XTRA device eliminates the need for extra-rapid fuses (more expensive) but, under current regulations, traditional line protections (such as slow fuses and circuit breakers) remain mandatory in the system up-line of the controller.